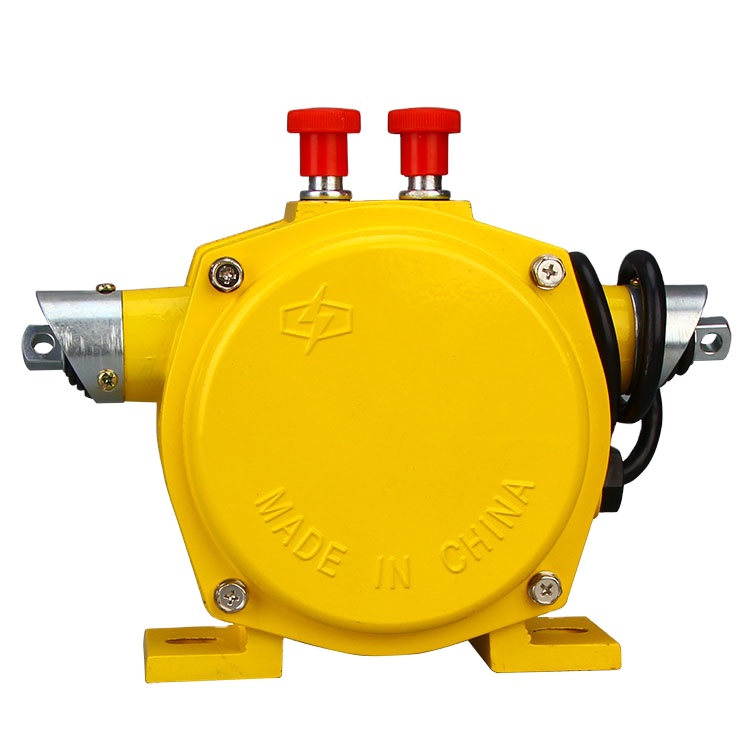

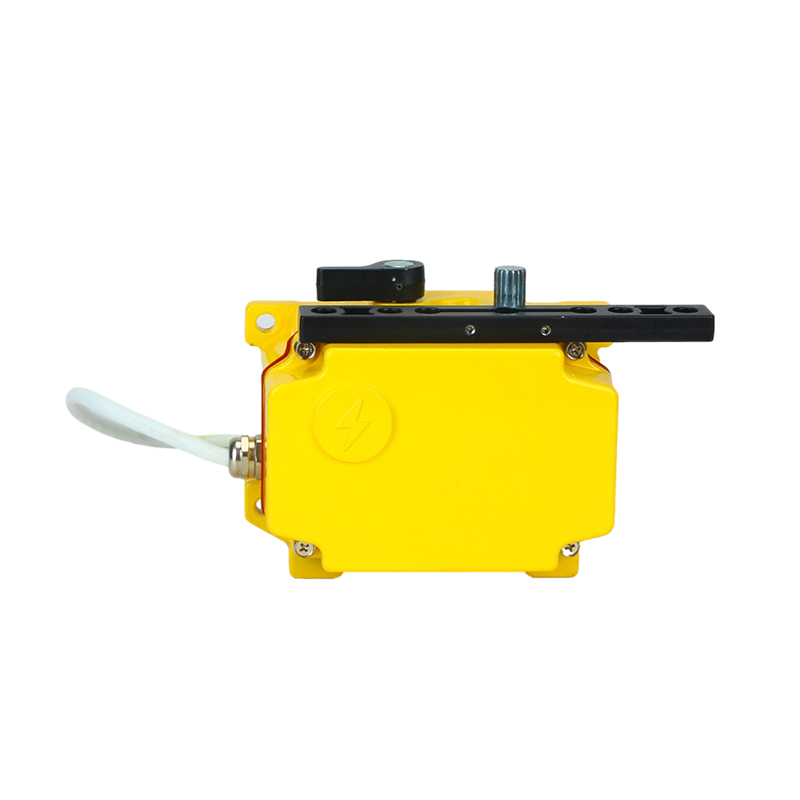

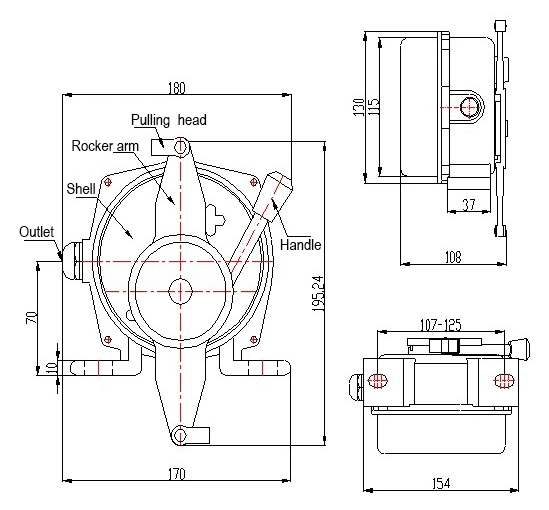

Pull cord switch

Working principle:

When an emergency occurs at the belt transport site, pull the wirerope tied to the lifting lug to make the slider and switch in themachine function and send out a stop signal.Release the wire ropeand press the reset bar before the reset.

Structural characteristics:

The switch uses a high quality trip switch, using a long mission. Good sealing, dust-proof, shock - proof and corrosion - proof.

The chassis is made of cast aluminum, with light weight and high hardness

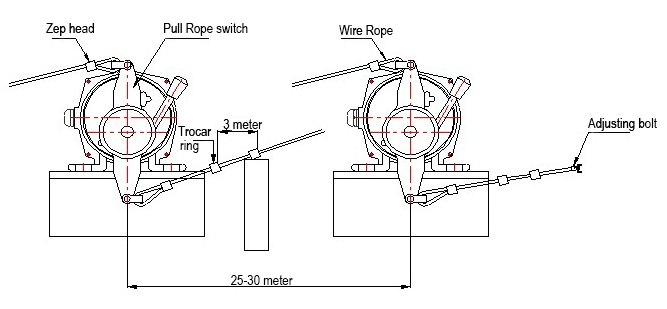

Installation and use:

The switch is balanced on the fixing bracket of the frame;

Tie the wire rope to the pull rings at each end, not exceedig 30 metres on each side (to be shortened if there is a gradient);

The rope pressure should be suitable to ensure the reliable reset of the switch;

The pulling rope is arranged in the parallel direction of the tape, and a lifting ring is added every 3 meters;

Technical indicators:

Item | Parameters |

Model | Two-way Pull cord switch |

| Ambient temperature | -30℃-+60℃ |

| Relative humidity | ≥85% |

| Angle of action | 30° |

| Limit Angle | 60° |

| Action force | 10(KG) |

| Number of contacts | 1NO 1NC /2NO 2NC |

| Contact Capacity | AC 380V DC 220V |

| Reliability | >106times |

| Protection | IP65 |

- ← Previous:No More

- Manual automatic integrated Pull Cord Switch :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.