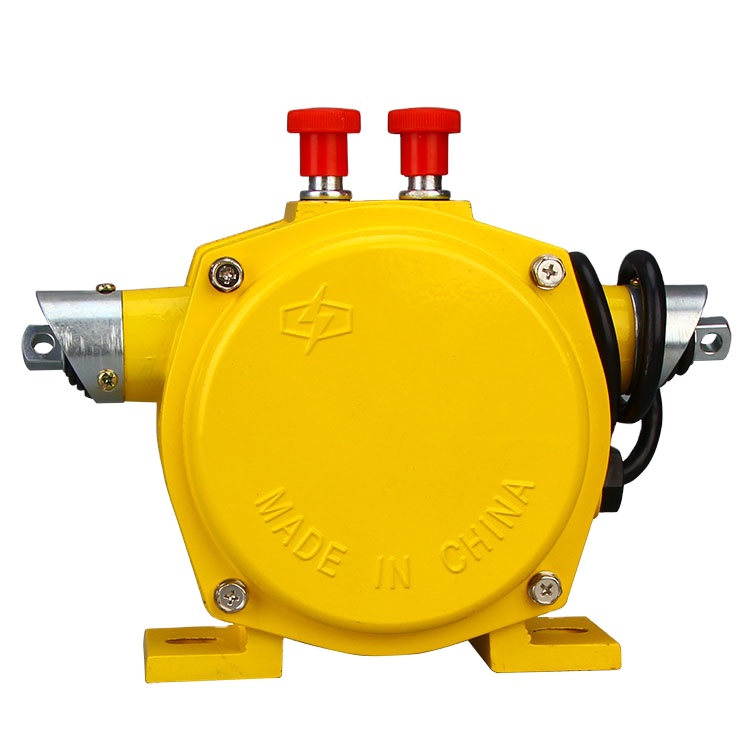

Square Ramsey Run-off switch

Working principle:

The two-stage run-off switch is installed on both sides of the conveyor, when the conveyor runs out of alignment, the conveyor belt touches the switch stick to make the stick deflect, when the stick deflection angle reaches the first level switch angle, the switch will send an alarm signal. The ROS-2D two-stage runout switch has a reliable conveyor belt runout detection function and a cast aluminium housing.

Installation and use:

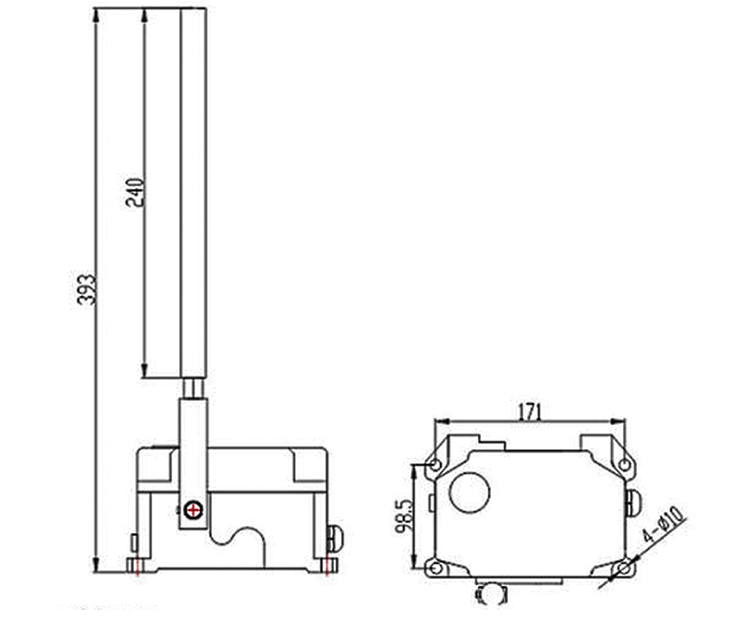

The anti-deflection switch can be fixed at the top or bottom of the longitudinal beam of the conveyor, and the action rod is about 25mm from the edge of the tape, usually installed on both sides of the tape at a distance of 0.3-2 m from the head or the tail. When the running tape is deflected, the edge of the tape drives the stick to rotate and squeeze to make it tilt, if the stick tilts more than the first action angle, the switch issues a set of switch signals, if the stick continues to tilt more than the second action angle, another set of switch signals is output. The two sets of switch signals can be used for alarm or stop respectively. After the tape machine has been reset to normal operation, the stick will be automatically reset.

Technical indicators:

| Item | Parameters |

| Model | Square Ramsey Run-off switch |

| Limit Angle | 70° |

| Action force | 10(KG) |

| Reliability | >106 times |

| Protection | NEMA4 |

| Contact Capacity | 24-380V AC/DC |

| Normal alarm angle | Adjustable within deviation of 22.5° |

- ← Previous:Two-way balance Pull Cord Switch

- Passive Slip Switchs :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.