Non-contact Speed Detectors

Working principle:

After the delay, the belt speed signal is detected by two photoelectric sensors and then input into the control box, the actual belt speed is displayed and calculated by the microcomputer (CPU) and sent to the monitor, while comparing with the preset belt speed, when the belt speed is lower than the set value, the controller displays the belt speed and makes the corresponding relay When the belt speed is lower than the set value, the controller will display the belt speed and make thecorresponding relay send out a signal, and the corresponding indicator light (red) will be on, indicating that the belt is slipping; on the contrary, when the actual belt speed is higher than the set value, the controller will enter normal operation and the corresponding indicator light (green) will be on. The relay is released.

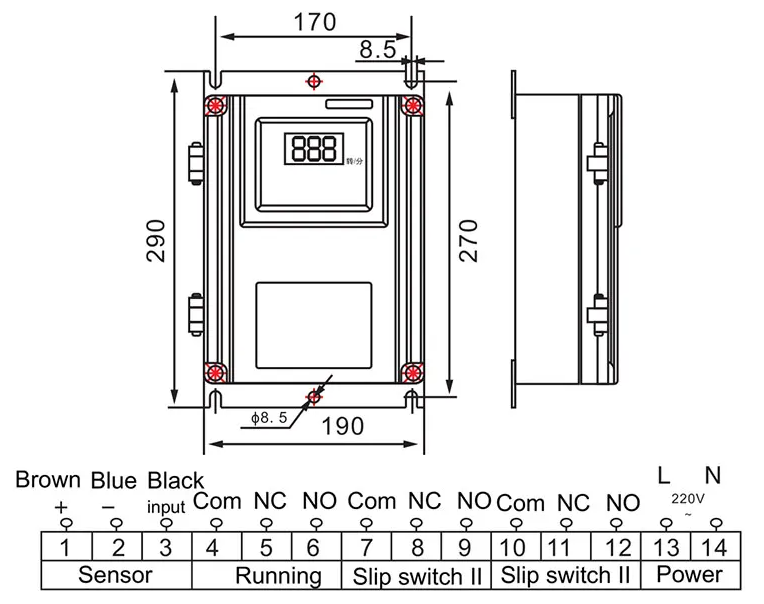

Installation and use:

The control box should be installed on the frame of the tape machine or on the wall near the monitoring head (not more than 100m) the sensing head is installed on the belt under the tape machine and the belt is running smoothly. There are two ways to install the sensing head:

1. Weld the sensing head under the tape machine bracket beam,

2.Weld 40*40 angle steel micro beam at the site itself, punch two holes ( 中 16) in the middle of the angle steel, the hole spacing see the spacing of the tape machine pulley, the angle steel will be fixed.

Structural Features:

1.first press SET key to show digital flashing, then press "<" " ^" key to show 9, 1, 2, 3, then press SET key to show flashing, then press"<" "∧" key to adjust the running speed value, and then press SET key to set successfully.

2.Also follow the above steps to change the display of 9,1,2,3 to 9,4,5,6 and adjust the speed value of slip switch I.

3.Also follow the above steps to change the display 9,1,2,3 to 9,7,8,9 to adjust the speed value of slip switch 1.

(1) ln order to ensure the reliable work of the detector, the detector only displays the belt speed when the power is connected to the controller, without any processing, and starts to work both when the belt runs to the normal speed delayed work. So do not detect after the power is connected.

(2) detector internal detection and control circuit all use integrated circuits, greatly improving the detection accuracy and reliability, but in use must work within the technical parameters.

Technical indicators:

| Item | Parameters |

| Model | Non-contact Speed Detectors |

| Testing Scope | 0-999 Rev/min |

| Power consumption | 10W |

| Contact capacity | 24-380V AC/DC |

| Operating voltage | AC220V 5A |

| Distance between sensor and control box≥100m | |

- ← Previous:Contact Speed Detectors

- Speed Spin Detector WKSRD-II :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.