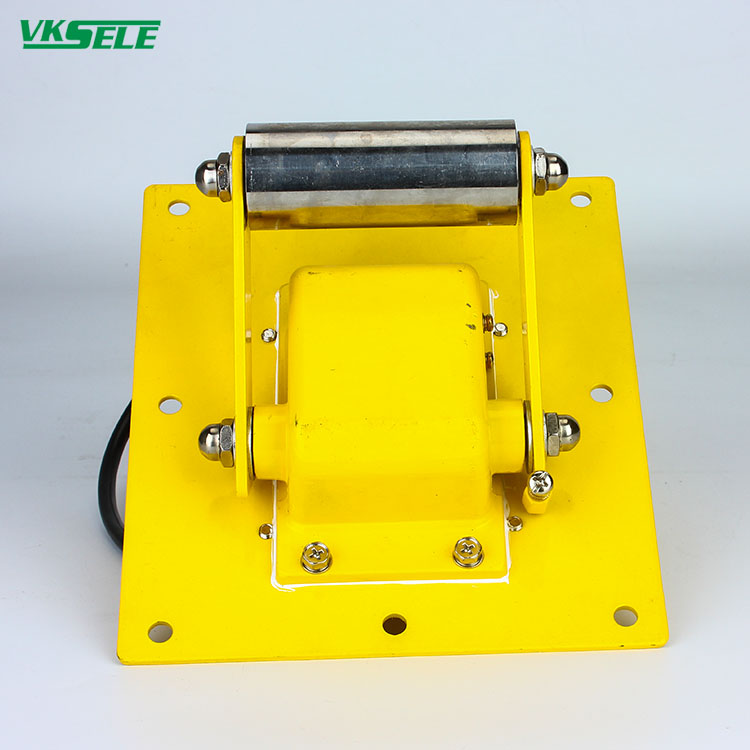

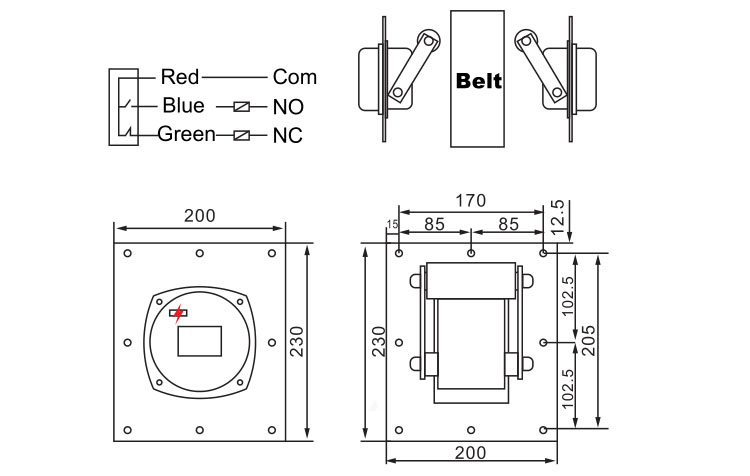

Lifter Run-off switch

Working principle:

The tape hoist anti-running switch is installed on the side of the upper and lower left and right wall plates of the tape hoist respectively to detect the runaway of the tape. When installed, the rollers are 20-70mm away from the tape and can be adjusted (by the user, generally not to rub the rollers). When deviation occurs, the tape is shifted outward to the rollers, and the rollers drive the adjusting rod to make the deviation switch act to cut off the equipment. In addition, because the signal can be sent to the microcomputer control system, it is convenient to realize the automatic control of the factory, so it can also achieve the purpose of reducing staff and increasing efficiency, centralized control, and facilitating production and scheduling. Widely used in steel, electric power, chemical industry, cement, coal, metallurgy, building materials, mining, ports and terminals, grain, warehouses and other types of conveying equipment industry.

Installation and use:

1. Anti-deflection switch is generally installed in the upper and lower casing into the drum side of each pair of position at about 1 meter from the center of the upper and lower drum, can also be installed in the central casing near the axillary belt drum as needed (to prevent the tape from swinging too much runaway switch detection errors).

2. When installing the runout switch, the rollers should follow the running direction of the tape.

3. Adjust the installation distance of the roller to allow the tape offset (generally40-60mm).

4.After installation, open the back cover, adjust the micro switch cam into the groove, cover the back cover and connect the wires.

Technical indicators:

| Item | Parameters |

| Model | Lifter Run- off switches |

| Ambient temperature | -20℃-+60℃ |

| Relative humidity | <90% |

| Movement power | 50±10N |

| Output signal | Switching signal |

| Contact Capacity | AC220V 5A |

| Response time | <2mS |

| Reset mode | Automatic Reset |

- ← Previous:No More

- No More :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.