Material Flow Detectors LL-III

Working principle:

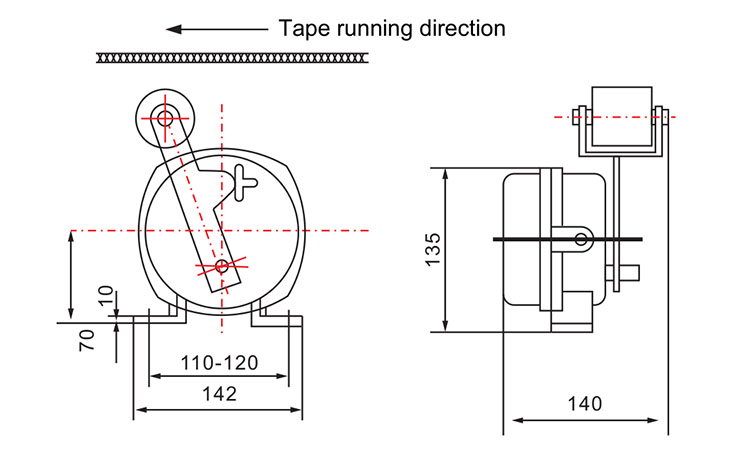

Type B:The detection device adopts load type detection, when there is material on the tape, the belt has a corresponding sink value due to the weight of the material,

when the belt sinks, the top roller of the detector is pressed down, driving the internal sensing parts to move to make the proximity switch work and give a switch value

to realize its detection. The detector is installed under the upstream tape, choosing the place where the sinkage of the tape is high when there is material. It is best to

install it between two rollers, not near the outlet. When there is no material, the contact wheel should be just in contact with the tape.

Installation and use:

Adopt the door type bracket mounting frame, fix the monitor on the beam, the height of the chain ball depends on the site, the switch conversion angle of this device is 20°,

the installation angle can be adjusted appropriately for the tape machine with inclination angle, you can choose the broom type or chain type.

Technical indicators:

| ltem | Parameters |

| Model | Material Flow Detectors |

| Ambient temperature | -30℃-+75℃ |

| Relative humidity | ≥85% |

| Action Angle | 20° (two way) |

| Number of contacts | 1NO 1NC |

| Contact Capacity | AC/DC 24-380V |

- ← Previous:Material Flow Detectors LL- I

- WKSZX Type Rotary Level Detectors :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.