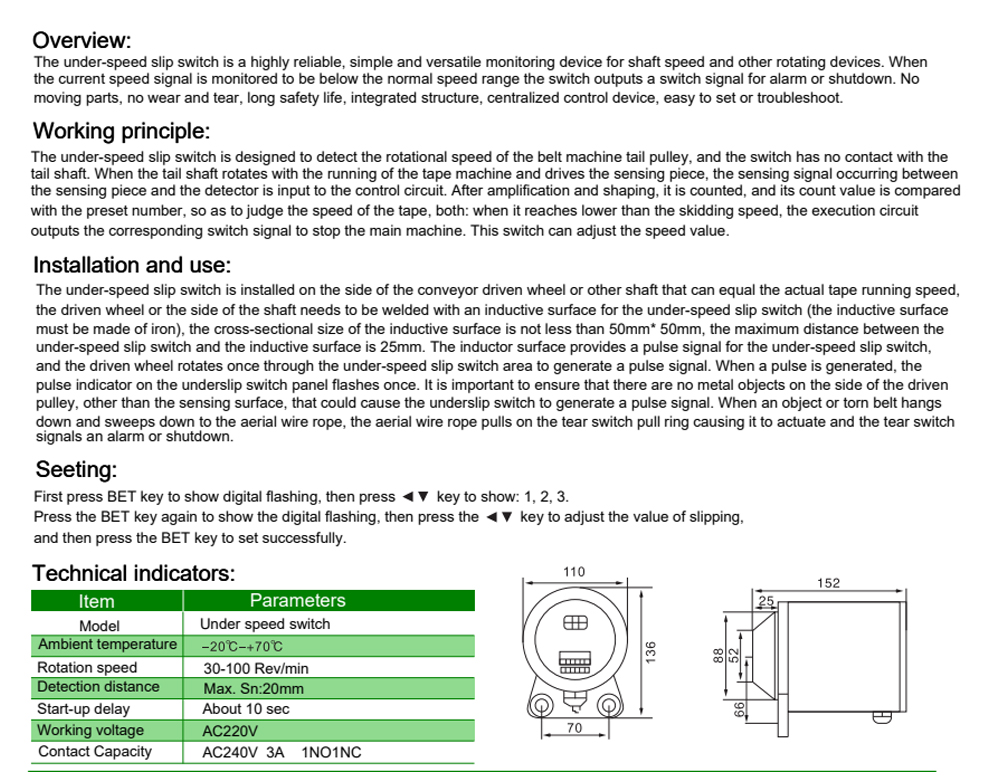

Non- contact Under speed Slip Switches QS

The under-speed slip switch is a highly reliable, simple and versatile monitoring device for shaft speed and other rotating devices. Whenthe current speed signal is monitored to be below the normal speed range the switch outputs a switch signal for alarm or shutdown. No moving parts, no wear and tear, long safety life, integrated structure, centralized control device, easy to set or troubleshoot.

- ← Previous:No More

- No More :Next →

Zhejiang Weikesen Power Technology Co.,Ltd.

Zhejiang Weikesen Power Technology Co.,Ltd.